Path to 100% SAF

How to enable a fully drop-in sustainable solution for aviation

On November 28, 2023, Virgin Atlantic flew the world’s first 100% sustainable aviation fuel (SAF) flight from London to NYC. The fuel used was 88% HEFA (Hydroprocessed Esters and Fatty Acids) from AirBP and 12% SAK (Synthetic Aromatic Kerosene) from Virent.1 While just a demonstration flight, it showcased the promise of a more sustainable aviation future. Unfortunately, we are still a long way from that future. In today’s post we will explore the challenges associated with 100% SAF.

What is Jet Fuel?

Let’s start with the basics! All fuels are made up of hydrocarbons, molecules that contain a combination of hydrogen atoms and carbon atoms bonded together. Variations in the amount of hydrogen and carbon in the molecule are what give rise to different fuel properties and nomenclature. The more carbon atoms in a molecule, the higher the energy density (more energy per gallon). However, this increased energy density has other less helpful properties - the more carbon atoms, the heavier the molecule is and the higher its freezing point. Planes fly at high altitudes, where they experience much colder temperatures. If the liquid fuel solidifies or becomes slushy, it could affect the performance of the engines. Thus the balance of hydrocarbons in a fuel mix is very important. It’s similar to blending different wine varietals to get the most balanced blend!

ASTM (American Society for Testing and Materials), the international governing body for aviation fuel, sets the standards for what is allowed in jet fuel. They set restrictions on blending proportions and oversee the manufacturing processes to make sure that the resulting compound is safe.

Conventional Jet Fuel (Jet-A) is made up of a specific blend of 5 types of hydrocarbons. An easy acronym to remember is PIANO - Paraffins, Isoparaffins, Aromatics, Naphthenes, and Olefins.

Paraffins (~25-30%): Saturated hydrocarbons with a straight chain structure. Paraffins are abundant and readily available as natural components of crude oil. As a major component of jet fuel, they provide a good balance of properties like energy content and low freezing point.

Isoparaffins (35-40%): Saturated hydrocarbons with a branched chain structure. Isoparaffins outperform paraffins on almost all jet fuel qualities. They have better combustion properties, burning more completely and without as many residual products. They also are less volatile and behave more regularly in cold temperatures. However, they are significantly more expensive and difficult to produce than paraffins.

Aromatics (~15% in blend): Unsaturated hydrocarbons with one or more carbon rings. Aromatics do not combust very well in low temperatures and are usually limited in quantity to reduce potential environmental and health impacts during combustion. However, aromatics are important because they react with fuel seals to prevent fuel leakage while in the air.

Naphthenes (~15% in blend): Saturated hydrocarbons with one or more carbon rings. Naphthenes enhance combustion stability within the engine combustion chamber. Their cyclic molecular structure promotes more uniform and controlled combustion compared to linear paraffins.

Olefins (<1% in blend): Olefins occur naturally during the creation of jet fuel, but are undesirable in the fuel mix due to their reactivity and volatility. Jet fuel producers try to minimize the amount of olefins as much as possible.

SAF as a “drop-in fuel”

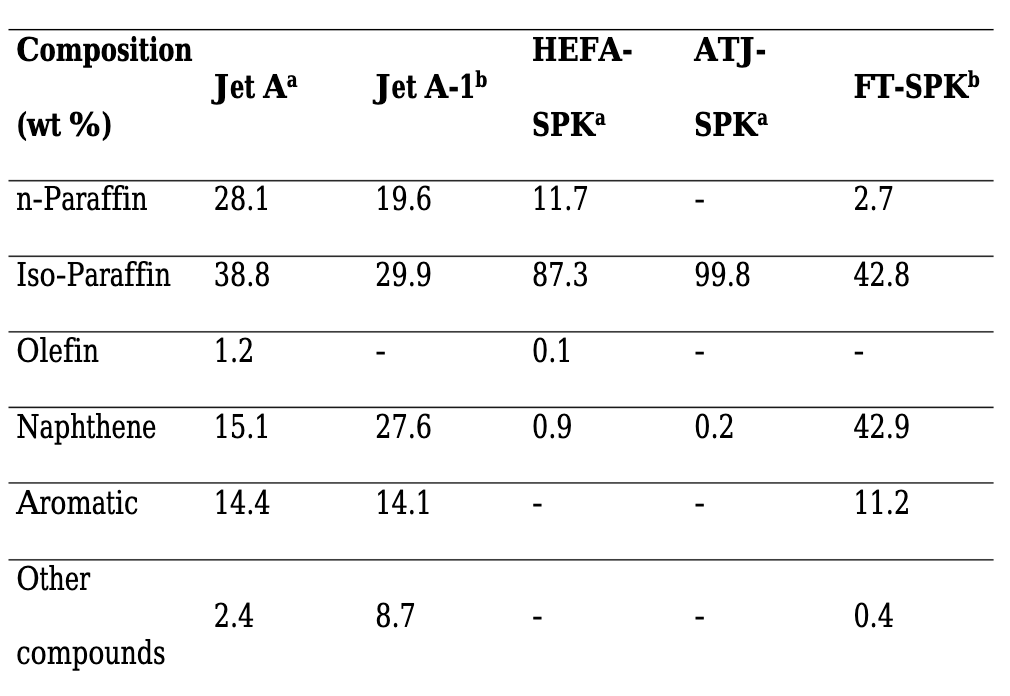

One of the most important benefits that SAF has over other sustainable aviation technologies (batteries, hydrogen) is that it can be used without any modifications to existing fuel infrastructure. Hence the term “drop-in!”. The process for creating SAF has to be reviewed by ASTM, and getting ASTM approval for a pathway is a big milestone for SAF producers. Today, there are 9 different pathways to creating SAF approved by ASTM.2 However, none of these approved SAF pathways make fuel that is identical to conventional jet fuel. Most of the pathways are heavy on isoparaffins and light on aromatics. An analysis out of the University of Sheffield compared conventional jet fuel (Jet-A) to 3 different SAF pathways to highlight the difference in content.3

Because the ratios are different, ASTM requires that SAF be blended with Jet-A. The maximum allowed percentage of SAF in the blend is called the “blending limit”. For each pathway, ASTM publishes a specific “blending limit”, the maximum being FT-SPK, HEFA, and FT-SPK/A (at 50%) and the minimum being FOG co-processing and FT co-processing (at 5%).

Since 50% of the fuel must be fossil based jet-fuel the blending limit significantly limits our ability to decarbonize aviation! So, how do we get past the blending limit?

New companies making aromatics

Enter a new wave of companies & research labs trying to synthesize aromatic components to blend with paraffin/isoparaffin heavy SAF, I’ve included a sample of a few companies I’ve found interesting.

Virent - Virent uses plant based sugars in their process (SAK) to create aromatic compounds. Virent produced the SAK in its demonstration pilot plant at its facility in Madison, Wisconsin, using corn dextrose from Iowa.

Alder Fuels - Alder Fuel’s process called Alder Green Crude (AGC) uses pyrolysis to combust woody biomass while retaining cyclic compounds similar to aromatics. In 2021, United Airlines signed a major offtake agreement with Alder Fuels for a 1.5 billion gallons of AGC over 20 years.

MIT - Lignin is one of the most common organic materials and the most abundant natural source of aromatic compounds. Researchers at MIT, have created a process that extracts aromatics out of lignin by reacting it over a molybdenum carbide catalyst. The team is still evaluating the stability of the fuel in partnership with NREL, but early results are promising.

As you can see there are a lot of different approaches to figuring this out and I think over the next few years, we will see even more companies tackle the 100% SAF challenge.

https://www.prnewswire.com/news-releases/virgin-atlantic-flies-worlds-first-100-sustainable-aviation-fuel-flight-from-london-heathrow-to-new-york-jfk-301998557.html

https://afdc.energy.gov/fuels/sustainable_aviation_fuel.html

https://www.sciencedirect.com/science/article/abs/pii/B9780128202975000128